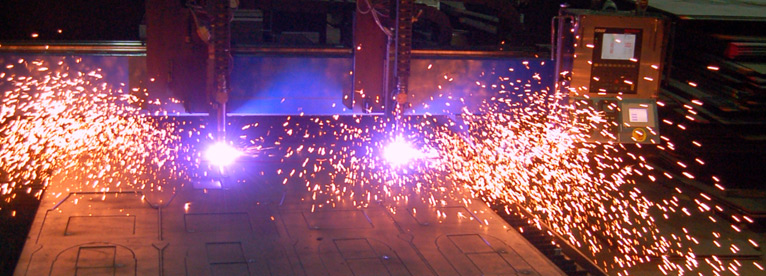

BRANNON STEEL is nearing completion of the installation of three Hypertherm HPR400XD high definition plasma cutting machines featuring True Hole™ technology.

This is the second phase of an aggressive project BRANNON STEEL undertook in early 2010 to dramatically improve the accuracy, flexibility, quality and speed of its plasma cutting systems. With significant investment and extensive research & development, BRANNON STEEL continues to be one of North America’s leading providers of carbon steel services.

Click here for a full list of BRANNON STEEL’s plasma cutting and scribing capabilities.

Visit Hypertherm for more information about True Hole™ technology.

BRANNON STEEL is registered to the ISO 9001:2008 quality standard and the ISO 14000:2004 environmental standard.